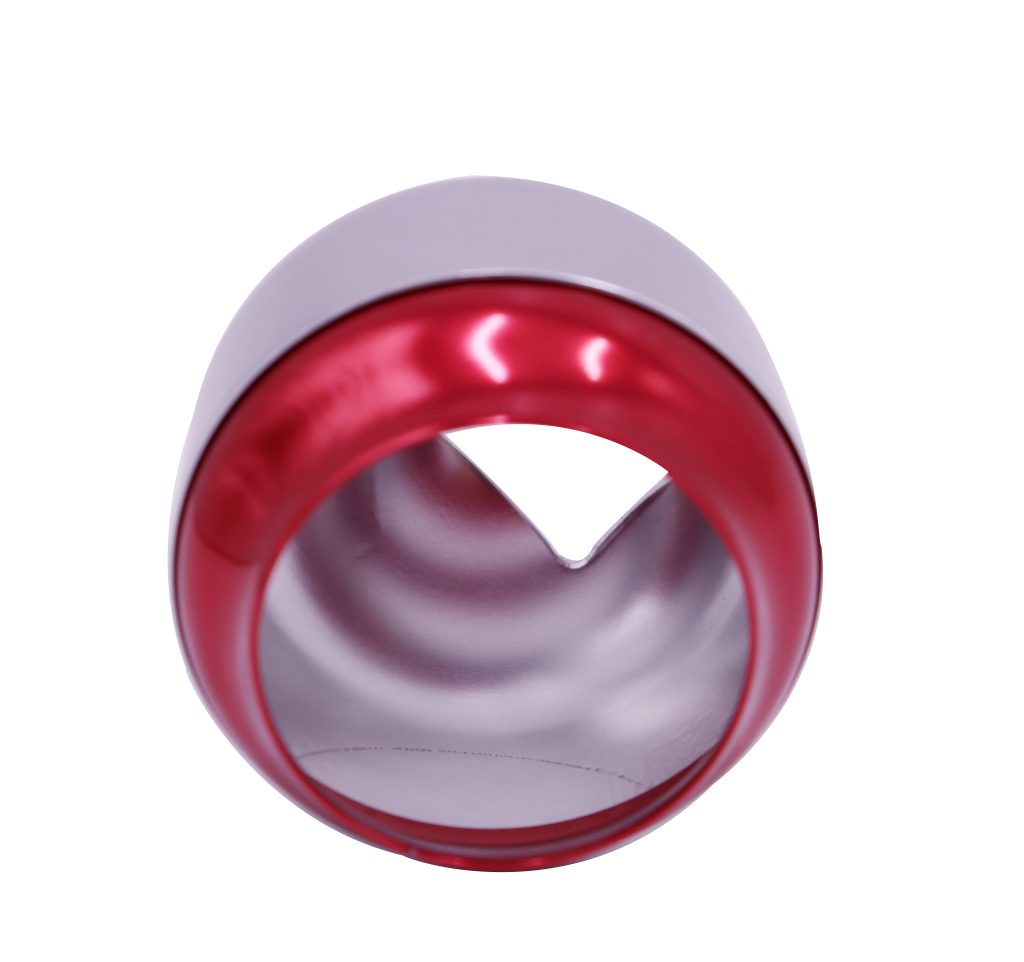

What is the Stamping?

Stamping is a process used to shape flat sheet metal by piercing, punching, embossing and performing other operations with a stamping press. It is a fast and cost-effective way to produce high volumes of metal parts. And it allows your manufacturer to produce complex shapes while maintaining consistently high quality.Some simple metal parts can be stamped with a single stroke, while more complex parts may need to go through multiple stages. The sheet moves quickly from one section of the progressive stamping press to the next, receiving different operations as it moves.Progressive stamping can be used to create metal parts with more complex geometries with fast turnaround, high repeatability, and low labor costs.

The advantages

- Rapid prototype producing

- High-accuracy and small tolerance

- Stable processing quality

- Cost effective and efficient when small and medium-volume runs

How Stamping works?

Punching machine working principle: is through the motor drive flywheel, and through the clutch, transmission gear drive crank connecting rod mechanism to make the slide block up and down movement, drive rabor mold to steel plate forming.

Stamping processing is the power of conventional or special stamping equipment… The sheet metal in the mold directly by the deformation force and deformation, so as to obtain a certain shape. Dimensions and performance of product parts production techniques. Sheet metal, die and equipment are the three elements of stamping. Stamping is a kind of metal cold deformation processing method. Therefore, it is called cold stamping or sheet stamping, referred to as stamping. It is one of the main methods of metal plastic processing (or pressure processing), and also belongs to material forming engineering technology.

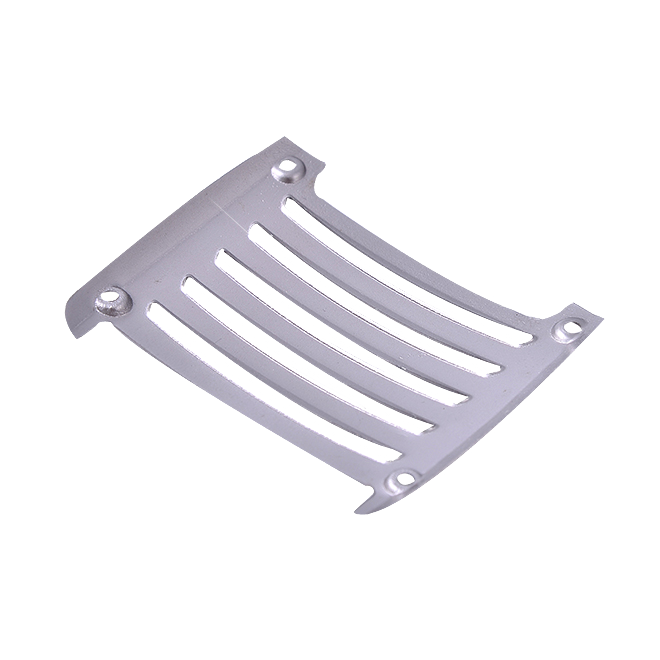

Features of Stamping

Stamping parts are mainly formed by stamping metal or non-metal sheets through stamping dies with the help of the pressure of the press. It mainly has the following characteristics: ⑴ stamping parts are made by stamping on the premise of low material consumption. Their parts are light in weight and good in stiffness. After plastic deformation of the sheet, the internal organization structure of the metal is improved, so that the strength of the stamping parts is improved. ⑵ stamping parts have high dimensional accuracy, which is consistent with the size of the module and has good interchangeability. ⑶ during the stamping process, the material surface is not damaged, and the appearance is smooth and beautiful.

Advantages

1. The dimensional accuracy is guaranteed by the mold, so the processed parts have stable quality and good consistency, and have the characteristics of “exactly the same”;

2. Stamping can obtain parts with thin wall, light weight, good rigidity, high surface quality and complex shape that cannot or is difficult to manufacture by other processing methods;

Drawbacks

Materials for Stamping

| CRS Steel | Stainless Steel | Copper | Brass |

|---|---|---|---|

| 1008 | 301 | C110 | 230 (85/15) |

| 1010 | 304 | 260 (70/30) | |

| 1018 | 316/316L |

Surface Finishes for Stamping

There has three kinds of surface treatment technologies that most commonly used in mold manufacturing:

- Nitriding

- Carburizing

- Hard coating film deposition