What is the CNC turning?

"CNC turning is based on the technical requirements of parts and its processing, to create the machining program, and input the machining program into the NUMERICAL control device,through numerical control device control the movement of machine tool spindle and feed, change cutters, and workpiece clamping and releasing, Make tool parts and other auxiliary devices work in strict accordance with the specified sequence of trajectories and parameters, to get parts machined and meet the drawing requirement"

The advantages

- Rapid prototype producing

- High-accuracy and small tolerance

- Stable processing quality

- Cost effective and efficient when small and medium-volume runs

How CNC Turning works?

Turning the rotary body surface, can use the forming tool method or tool tip trace method. When turning, the workpiece is driven by the spindle of the machine tool. A tool clamped on a tool rest for feeding motion. The cutting speed v is the linear speed (m/min) at the contact point between the rotating workpiece surface and the turning tool; The cutting depth is the vertical distance (mm) between the workpiece surface to be machined and the machined surface at each cutting stroke, but the contact length (mm) between the tool and the workpiece perpendicular to the feed direction when cutting and forming turning.

Features of CNC Turning

1. It is easy to ensure the position accuracy of each machining surface of the workpiece.

2. The cutting process is relatively stable, avoiding inertia force and impact force, allowing the use of large cutting parameters, high-speed cutting, which is conducive to the improvement of productivity.

3. Suitable for finish machining of non-ferrous metal parts.

Advantages

1.High turning efficiency.

2.The cost of equipment input is low. At the same time of productivity, the investment of lathe is obviously better than that of grinder, and the cost of its auxiliary system is also low.

3.Suitable for small batch production.

4.Hard turning can make parts obtain good overall machining accuracy.

Maximum Capabilities for CNC turning

| Part size limitations | Metric units | Imperial units |

|---|---|---|

| Maximum part diameter | 431 mm | 17 in |

| Maximum part length | 990 mm | 39 in |

| Maximum swing over the carriage | 350 mm | 13.7 in |

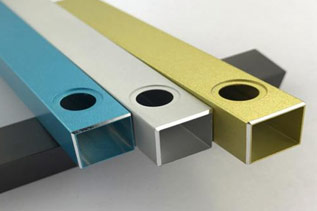

Materials for CNC Turning

| Aluminum | Steel | Copper / Brass / Titanium / Zinc | Plastics | Others |

|---|---|---|---|---|

| 2A12 | 201 | Copper | ABS | Bakelite |

| 5052 | 303 | Brass | Transparent ABS | Rubber |

| 7075 | 304 | Titanium(Ti) | Polycarbonate (PC) | FR4 |

| 6061 | 316 | Zinc(Zn) | Acrylic (PMMA) | Others |

| others | 430 | Mild steel(Low Carbon Steel) | Delrin/Acetal (POM) | - |

| - | others | Alloy steel | Polyethylene (PE) | - |

| - | - | Tool steel | PTFE (Teflon) | - |

| - | - | - | PEEK | - |

Surface Finishes for CNC Turning

As-Milled

Requirement

none

Grit

none

Thickness

none

Surface roughness

none

Color

none

Part masking

none

Bead Blast

Requirement

Specification

Grit

#120

Thickness

none

Surface roughness

none

Color

Uniform matte of raw material color

Part masking

Indicate masking requirements in technical drawing

Anodized(Type II Or Type III)

Requirement

Specification

Grit

#120

Thickness

none

Surface roughness

none

Color

Uniform matte of raw material color

Part masking

Indicate masking requirements in technical drawing

Bead Blasting + Anodizing color or clear(type II)

Requirement

Specification

Grit

none

Thickness

8 - 12 μm (clear), 4 - 8 μm (color)

Surface roughness

none

Color

Black, clear or any RAL code or Pantone number

Part masking

Indicate masking requirements in technical drawing

Powder Coat

Requirement

Specification

Grit

none

Thickness

18 - 72 μm

Surface roughness

none

Color

Black or any RAL code or Pantone number

Part masking

Indicate masking requirements in technical drawing

Electropolished

Requirement

Specification

Grit

none

Thickness

none

Surface roughness

none

Color

Natural metal color

Part masking

Indicate masking requirements in technical drawing

Brushed

Requirement

Specification

Grit

#80-120

Thickness

none

Surface roughness

0.8 - 1.5 μm

Color

none

Part masking

Indicate masking requirements in technical drawing